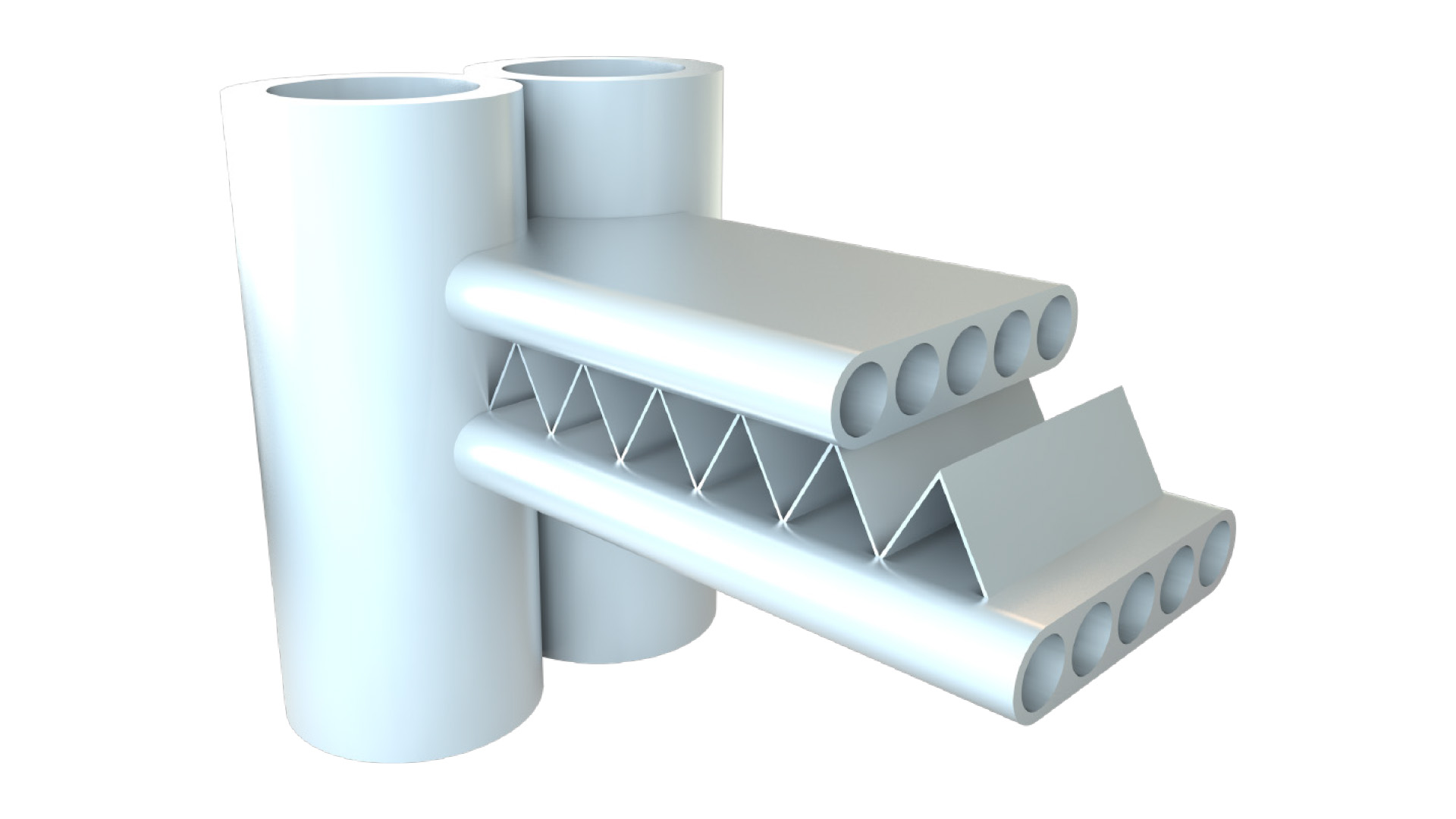

HyperCore™ Micro-Channel Coils

HyperCore™ microchannel condenser coils , a standard feature on the ½ - 6 HP air-cooled condensing units, are all-aluminum coils with multiple flat tubes containing small channels (microchannels) through which refrigerant flows. Heat transfer is maximized by the insertion of angled and louvered fins inbetween the flat tubes. These components are joined with two refrigerant manifolds using an aluminum-zinc alloy brazing material in a nitrogen-charged braze furnace to make the completed microchannel coil.

Features & Benefits

Improved Heat Transfer Performance

- 20-30% higher than traditional copper-aluminum round-tube plate fin (RTPF) coils with epoxy coating of the same size, enabling comparable capacity achievement with a smaller coil

Improved Corrosion Protection

- Monometal (aluminum) construction gives no opportunity for galvanic corrosion – HyperCore™ microchannel coils have been proven to last up to two times (2X) longer than standard RTPF coils in extended tests

Reduced Refrigerant Charge & Reduced Costs

- Condenser coil refrigerant charge may be reduced by up to 75%, leading to as much as a 40% reduction in system charge and reducing costs for end users

Improved Durability & Reduced Potential for Leaks

- Require only one manual braze operation versus 50-100 manually brazed joints for RTPF, significantly reducing the likelihood for leaks

- Flat tubes serve as a fin guard to help protect the fins from damage

Environmentally Friendly

- 100% recyclable

- Reduced refrigerant helps decrease the potential for ozone depletion and global warming